Annealing is an integral step in production and should always be completed. The procedure relieves the stress from the lens necessary to reach its final power. Annealing is also an important part of the nanoCLEAR AR process, helping to strengthen the AR and to finalize the hydrophic top coat application.

After demolding the lens must be cleaned to remove monomer residue and flashing.  If not cleaned properly, the residue may harden on the surface of the lens during annealing leaving a permanent defect. To produce a tack free, easily cleaned edge, we recommend the use of a handstone or the cribbing of the lens on an edger. Spray Q-Spray on the edged lens and thoroughly clean it before continuing. Dry the lens with a lint free cloth.

If not cleaned properly, the residue may harden on the surface of the lens during annealing leaving a permanent defect. To produce a tack free, easily cleaned edge, we recommend the use of a handstone or the cribbing of the lens on an edger. Spray Q-Spray on the edged lens and thoroughly clean it before continuing. Dry the lens with a lint free cloth.

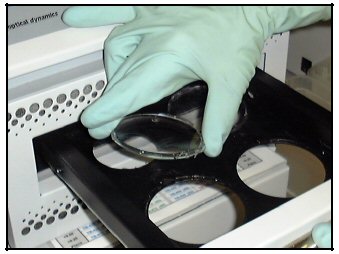

Place the newly demolded and cleaned lenses into the anneal positions (the back two positions in the drawer of the post cure chamber) and press the ANNEAL button.  Rotate the knob to scroll through multiple jobs (if they are available for annealing) and press the ANNEAL button when the proper job is displayed. Press ANNEAL again to start the timed annealing cycle. The end-of-cycle tone will sound when the process is complete. Press the ANNEAL button to stop the tone. Remove the lenses from the post cure drawer and place them in the job tray. Allow the lenses to cool to room temperature before edging and insertion.

Rotate the knob to scroll through multiple jobs (if they are available for annealing) and press the ANNEAL button when the proper job is displayed. Press ANNEAL again to start the timed annealing cycle. The end-of-cycle tone will sound when the process is complete. Press the ANNEAL button to stop the tone. Remove the lenses from the post cure drawer and place them in the job tray. Allow the lenses to cool to room temperature before edging and insertion.