The monomer inside the cavity has been solidified during the curing cycle. Once the curing cycle is complete, the mold cavities are demolded to expose the lens surface. The assembly should be separated while still warm. Try not to “force” molds off the lens. If a mold does not release, simply return it to the soaking container and try again.

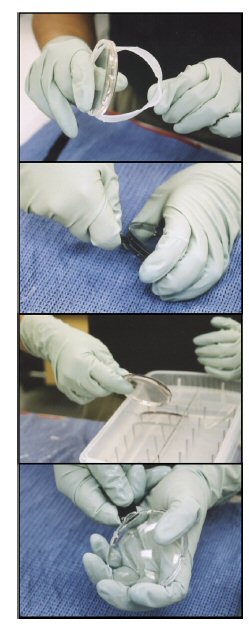

Start with the right cavity. Peel off the gasket. Wipe the edge of the lens with a lint free cloth to remove monomer residue.

Start with the right cavity. Peel off the gasket. Wipe the edge of the lens with a lint free cloth to remove monomer residue.

Sseparate one of the molds from the assembly with the demolding tool. Insert the tool into the notch located opposite the fill port. Only use the tool as a wedge or to pry. If a mold does not come off, soak the entire assembly for at least 30 seconds in the demolding container and try again.

Put the freed mold in the soaking container for later cleaning and place the remaining mold/lens assembly to soak for at least 1 minute. The lens will release from the remaining mold.

If the last mold does not come off after soaking in the demolding container, try to gently using the demolding tool.

Put the molds in the soaking tub and the lens back in the job tray. Repeat this process for the left side. The molds should all be in the soaking tub and the lenses in the job try when you finish this step.