Eye Mobile, located on the island of Antigua, expanded their Q-2100 Digital Lens Lab to accommodate their growing business. With additional equipment, production volume is increased to meet their growing demand for clearLIGHT, sunSMART, ultraSUN, blueVIEW, amplifEYE, and nanoCLEAR AR.

Eye Mobile, located on the island of Antigua, expanded their Q-2100 Digital Lens Lab to accommodate their growing business. With additional equipment, production volume is increased to meet their growing demand for clearLIGHT, sunSMART, ultraSUN, blueVIEW, amplifEYE, and nanoCLEAR AR.

Launched in 2007 Eye Mobile started out as just that, a first of its kind vision care provider not limited to an office space. As the operation’s tag line indicates, Eye Mobile “brings vision care closer to you.” Utilizing digital technology, patients obtained a comprehensive eye examination in the comfort of their own home, office or even at school. And the services weren’t limited to Antigua alone, but Barbuda, St. Kitts, Nevis and Montserrat as well.

By 2012, a second market was seen with the need to locate a branch downtown. Many a cruise ship passengers would come to them having lost a contact lens while swimming, desperately needing another, while others who had broken their glasses needed another pair quickly. Located on Redcliffe Quay waterfront, the branch was modernly designed and convenient for persons living and visiting St. Johns.

As mentioned on their Facebook page, “Even more intriguing was the speed at which the company can provide service, thanks to the digital lab that has been implemented. Using liquid monomer technology, Eye Mobile is able to make its own lenses. As such, (for most prescriptions) patients can obtain their glasses quickly, imagine that! Two weeks wait for completed glasses have become the exception and not the norm at Eye Mobile!”

We congratulate our friends at Eye Mobile and their ever expanding business!

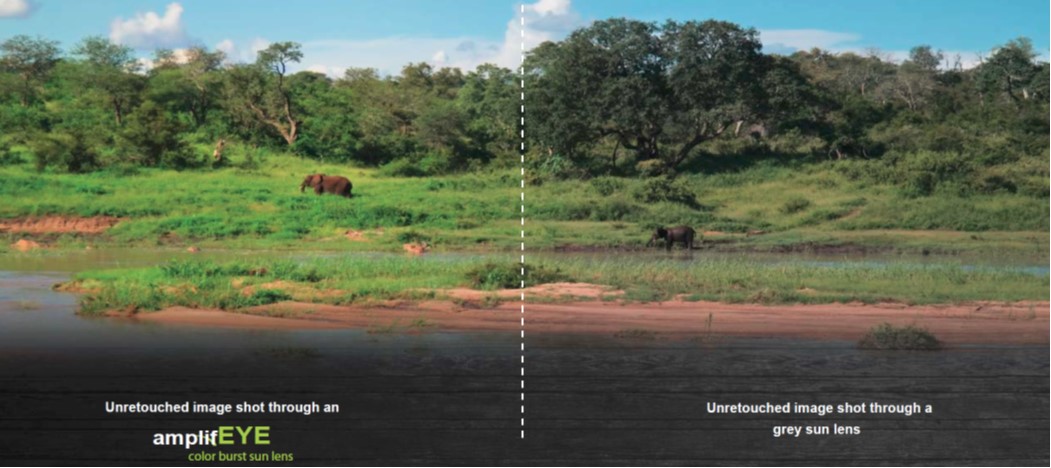

Have you added ampliFEYE? It’s like HDR for your EYES! Through advanced spectral filtration, amplifEYE lenses selectively block color waves for a more vibrant and saturated view of the world.

Have you added ampliFEYE? It’s like HDR for your EYES! Through advanced spectral filtration, amplifEYE lenses selectively block color waves for a more vibrant and saturated view of the world.

Eye Mobile, located on the island of Antigua, expanded their Q-2100 Digital Lens Lab to accommodate their growing business. With additional equipment, production volume is increased to meet their growing demand for clearLIGHT, sunSMART, ultraSUN, blueVIEW, amplifEYE, and nanoCLEAR AR.

Eye Mobile, located on the island of Antigua, expanded their Q-2100 Digital Lens Lab to accommodate their growing business. With additional equipment, production volume is increased to meet their growing demand for clearLIGHT, sunSMART, ultraSUN, blueVIEW, amplifEYE, and nanoCLEAR AR.