Molds normally have residue and flashing on the surface and edges after use. All debris must be removed before the molds can be used again successfully. Clean molds must be stored properly to ensure mold safety while not in use. Additionally, proper mold storage simplifies the picking process when the mold is needed again.

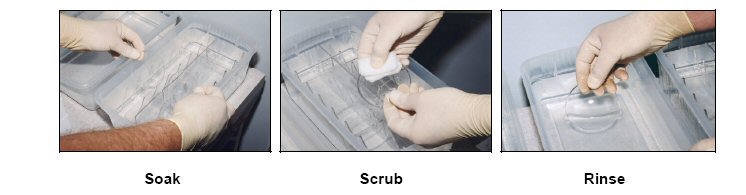

Mold should be left in the soaking containers for at least 5 minutes before cleaning.

Scrub molds thoroughly with the disposable mold scrubber supplied by Optical Dynamics. Never use other types of pads as mold damage may occur. Pay special attention to edges and segment line when cleaning. Rinse the molds with running water if it is available. If running water is not available, use a container of tap water to rinse the molds (change the rinse container water frequently). Spray the rinsed molds immediately with Q-Spray and wipe them dry. NEVER store a wet mold or permanent water spotting may occur.

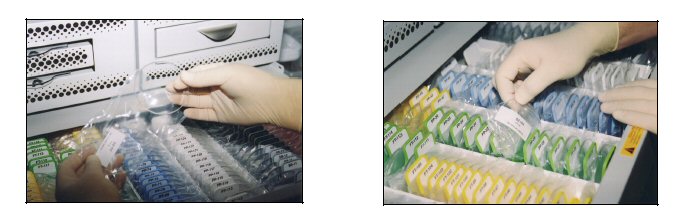

It is very important that all molds are stored properly and organized. Each space in a mold storage drawer is labeled for one specific mold. Make sure the mold you place there is the right one.

Once clean and dry, read the mold designation near the edge of the mold and find the proper location in the storage unit. Put the mold back into its wrapper (to help protect from dirt and scratching) and gently put into the alloted space.