Repost The New OD, Optometric Management March, 2015

In today’s evolving healthcare environment, it’s become vital to separate yourself and your parctice from the crowded landscape. Utilizing proven business models from the marketplace is a great place to start.

Consider the elite hotel brands across the globe whose mission has become impeccable customer service. …This high level of doing business can become your way of doing business if you follow these simple principles

- The Art of the Greeting – Ensure that your staff members greet patients by saying, “Welcome to (insert practice here). My name is (insert staff member’s name). How may I help you. Reminding patients where they’re receiving excellent patient care helps establish your brand.

- Dress for Success – From the front desk to the technician, and especially in the optical center, it’s important to have a uniform or dress code.

- The Attitude – You can’t train happy and nice and good social skills are hard to learn, too. Therefore, it’s imperative to begin with the end result in mind and hire for personality rather than job skills or experience – in certain positions.

- Be Our Guest – Develop a culture that promotes the patient as a guest. When you pass a patient in the hallway, say hello or offer a friendly smile and make sure your staff does the same.

- Classy Clinics – Closely monitor your physical space. Please your eyes where patients do by sitting in your waiting room, exam rooms and optical and notice everything.

- Don’t Tell the Patient, Show Them – When you are staying at a prestigious hotel, you’re taken there by a staff member. Your staff should do the same.

Providing 5-start service is a great way to build patient loyalty and increase referrals.

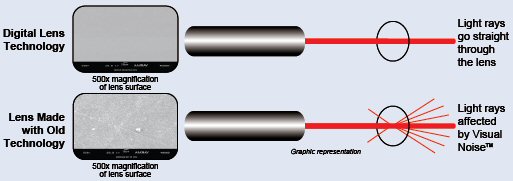

Usage: The more you make…the more you’ll make! It simple if you change the way you think about your business. With the Q-2100 Digital Lens System you have the capability of producing up to 90%+ of all the Rxs written in a typical practice. If you process only 15% of your lens needs on the system you will not see a huge impact. If you’re producing over 70% of your lens needs, you will be thrilled with your bottom line.

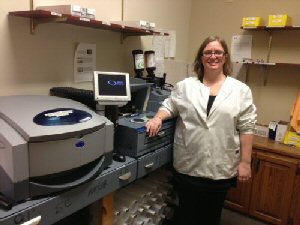

Usage: The more you make…the more you’ll make! It simple if you change the way you think about your business. With the Q-2100 Digital Lens System you have the capability of producing up to 90%+ of all the Rxs written in a typical practice. If you process only 15% of your lens needs on the system you will not see a huge impact. If you’re producing over 70% of your lens needs, you will be thrilled with your bottom line. Integration: Now that you can make it, its time to sell it! Ensure your entire practice is knowledgeable about the new products you have purchased. Everyone must understand why you chose to integrate digital lens technology into your practice and how to sell clearLIGHT advantage and sunSMART II. Your staff is key to maximizing your potential. This is not a niche product…this is a new way of doing business. Educate, reward, monitor, and reinforce your team’s commitment to this new lens technology and you will be successful.

Integration: Now that you can make it, its time to sell it! Ensure your entire practice is knowledgeable about the new products you have purchased. Everyone must understand why you chose to integrate digital lens technology into your practice and how to sell clearLIGHT advantage and sunSMART II. Your staff is key to maximizing your potential. This is not a niche product…this is a new way of doing business. Educate, reward, monitor, and reinforce your team’s commitment to this new lens technology and you will be successful.