Cleaning the fill stand

- Clean any monomer spills and overflows immediately

- Wipe off the bottom of the valve at the end of every

Flash Fill Stand Trouble Shooting

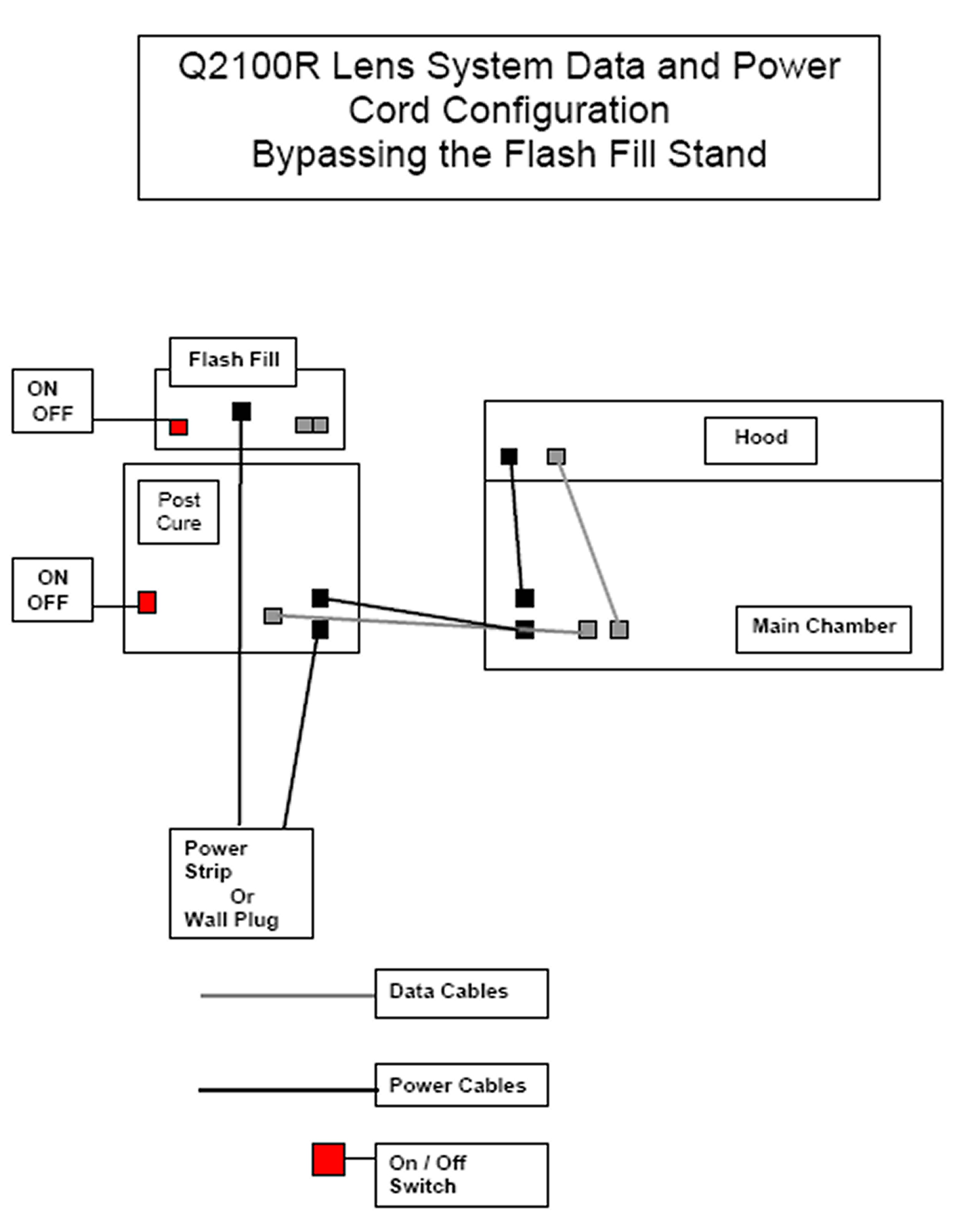

No power to the fill stand

- Make sure the unit is plugged in and the power switch is on

- Check the fuses in the back of the unit

3. Call the Optical Dynamics Service Department 800-587-2743

3. Call the Optical Dynamics Service Department 800-587-2743

Fill stand does not heat properly

- Make sure the unit is plugged in and the power switch is on

- Check the fuses in the back of the fill stand

- Call the Optical Dynamics Service Department 800-587-2743

Monomer leaking from the valve

- Make sure the valve is completely closed

- Remove the valve knob by twisting counter clockwise and pulling

- Make sure the two rubber gaskets are seated inside the valve needed opening

- Clean valve knob with IPA and lint free cloth

- Call the Optical Dynamics Service Department 800-587-2743

Oops, I mixed different monomers

- Turn unit off immediately

- Call the Optical Dynamics Service Department 800-587-2743