Topic: My nanoCLEAR AR system was running a job when I received the following message: MOLD DID NOT RELEASE FROM SUCTION, what does this mean?

The Reason Why: The mold the system has just coated is stuck to the suction ring and is not releasing into the mold stage. As you run jobs, costing adheres to the edge of the suction ring which can become sticky making it difficult to release the mold.

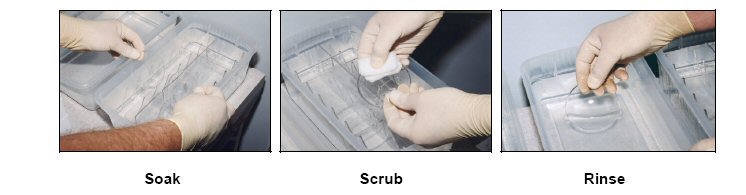

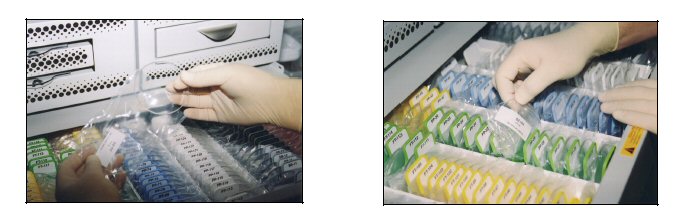

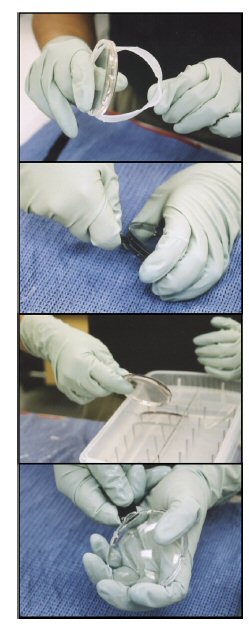

The Fix: As part of daily maintenance, the suction ring should be removed at the end of each production day and inspected. If the suction ring shows coating build up, it should be cleaned and scrubbed in your Q-soak tub. The suction ring is a disposable item and should be replaced when coating cannot be easily removed. It is also good practice when placing a new suction ring on your system to clean it with the same process to ensure proper suction with the surface of the mold. Remember to always keep an extra suction ring in inventory so you can pull as needed.

Topic: My mold was going through the coating cycle when I received the following message: MOLD DROPPED DURING CYCLE

The Reason Why: The mold has released from the suction ring during the process as the suction pressure has been compromised.

The Fix: When you remove the suction ring at the end of day to inspect, check for any cracks in the surface of the ring. Overtime, the ring may become cracked, causing the suction ring to lose vacuum pressure. If this is the case, dispose of the old suction ring and replace it with a new ring. As mentioned above, remember to clean the new ring in your Q-soak tub to ensure proper suction. Always keep an extra suction ring in inventory for ongoing production.